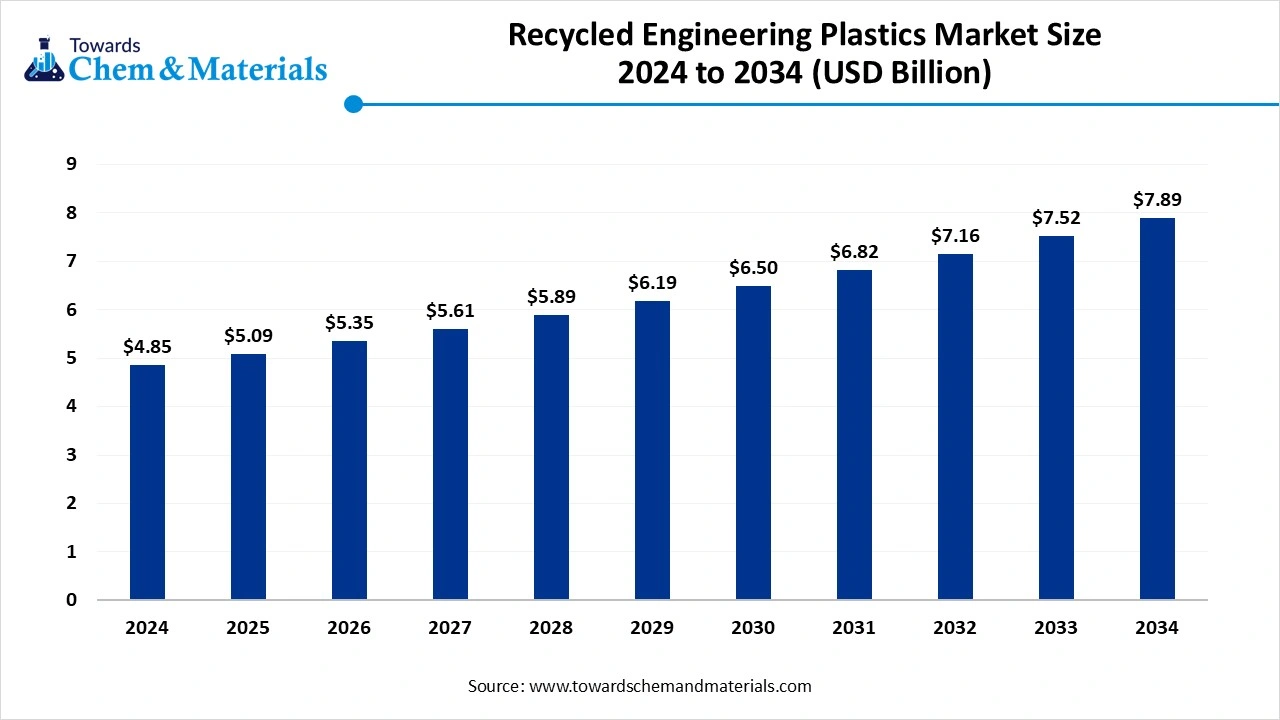

Recycled Engineering Plastics Market Size to Worth USD 7.89 Bn by 2034

Towards Chemical and Materials Consulting, the global recycled engineering plastics market size is accounted at USD 5.09 billion in 2025 and predicted to increase from USD 5.35 billion in 2026 to approximately USD 7.89 billion by 2034, expanding at a CAGR of 4.99% from 2025 to 2034.

Ottawa, Nov. 14, 2025 (GLOBE NEWSWIRE) -- The global recycled engineering plastics market size is calculated at USD 5.09 billion in 2025 and is expected to be worth around USD 7.89 billion by 2034, growing at a compound annual growth rate (CAGR) of 4.99% over the forecast period 2025 to 2034. Asia Pacific dominated the recycled engineering plastics market with a market share of 47.19% in 2024. The growth of the recycled engineering plastics market is primarily driven by increasing demand for sustainable and eco-friendly materials across various industries. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/5929

What are Recycled Engineering Plastics?

The recycled engineering plastics market in 2024 is witnessing significant growth due to the increasing emphasis on sustainability and environmental conservation. These plastics, recovered from post-consumer and post-industrial waste, are used across automotive, electronics, construction, and packaging industries. Rising global regulations to reduce plastic pollution and promote circular economy practices are driving demand for high-quality recycled materials.

Technological advancements in sorting, processing, and polymer recovery have enhanced the mechanical and thermal properties of recycled engineering plastics. Cost-effectiveness compared to virgin plastics further encourages manufacturers to adopt recycled alternatives in large-scale production.

Recycled Engineering Plastics Market Report Highlights

- The global recycled engineering plastics market was valued at USD 4.85 billion in 2024.

- It is estimated to reach around USD 5.09 billion in 2025.

- The market is projected to grow to approximately USD 7.89 billion by 2034.

- This reflects a compound annual growth rate (CAGR) of about 4.99% during 2025-2034.

- Top Players in recycled engineering plastics market MBA Polymers, Inc.; Banyan Nation; Polylactic Group; Covestro AG; Eastman Chemical Company; Trinseo; Veolia Environnement S.A.; Borealis; Dow Inc.; Polyvisions Inc.

- Asia Pacific dominated the global recycled engineering plastics market and accounted for largest revenue share of 47.19% in 2024.

- Polycarbonate (PC) dominated the recycled engineering plastics market across the Product segmentation in terms of revenue, accounting for a market share of 28.11% in 2024.

- Mechanical recycling dominated the recycled engineering plastics market across the recycling process segmentation in terms of revenue, accounting for a market share of 73.11% in 2024.

- Automotive dominated the recycled engineering plastics market across the application segmentation in terms of revenue, accounting for a market share of 28.32% in 2024.

The Ascendancy of Advanced Sorting in Recycled Engineering Plastics

A key technological shift in the recycled engineering plastics industry is the adoption of advanced chemical and mechanical recycling methods that improve material quality and performance. Chemical recycling enables the breakdown of plastics into monomers, allowing the production of high-purity engineering plastics comparable to virgin materials. Mechanical recycling techniques, enhanced with precision sorting and cleaning technologies, ensure consistent quality and minimize contamination.

Integration of AI and automated systems in sorting and processing has increased efficiency, reduced costs, and improved yield. Innovations in additives and compatibilizers further enhance the durability, thermal stability, and mechanical strength of recycled plastics.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Major Private Industry Investments for the Recycled Engineering Plastics Industry:

- Borealis acquires Integra Plastics: Borealis acquired the Bulgarian mechanical recycling company Integra Plastics to add more than 20,000 tons of annual recycling capacity for post-consumer waste.

- LyondellBasell acquires recycling lines from PreZero: LyondellBasell purchased mechanical recycling assets from PreZero in California to produce post-consumer recycled resins and expand its U.S. presence.

- ExxonMobil invests in advanced recycling: ExxonMobil is investing $200 million to expand the chemical recycling capacity at its Texas facilities to convert hard-to-recycle plastics into raw materials.

- Revalyu Resources expands chemical recycling in India: Revalyu Resources commissioned a second chemical PET recycling plant in Nashik, India, as part of a $100 million investment to increase capacity to 280 tons per day by 2025.

-

Closed Loop Circular Plastics Fund attracts investment: The Closed Loop Circular Plastics Fund, managed by Closed Loop Partners, received investments from several corporations to accelerate the development of plastics recycling and recovery infrastructure in North America.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5929

Recycled Engineering Plastics Market Report Scope

| Report Attribute | Details |

| Market size value in 2025 | USD 5.09 Billion |

| Revenue forecast in 2034 | USD 7.89 Billion |

| Growth rate | CAGR of 4.99% from 2025 to 2034 |

| Historical data | 2019 - 2024 |

| Base year | 2024 |

| Forecast period | 2025 - 2034 |

| Quantitative units | Revenue in USD Million, Volume in Kilotons, and CAGR from 2025 to 2034 |

| Segments covered | Product, recycling process, application, region |

| Regional scope | North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

| Key companies profiled | MBA Polymers, Inc.; Banyan Nation; Polyplastics Group; Covestro AG; Eastman Chemical Company; Trinseo; Veolia Environnement S.A.; Borealis; Dow Inc.; Polyvisions Inc. |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Major Trends of the Recycled Engineering Plastics Market:

- Widespread adoption of circular economy principles: Governments and industries are actively shifting from linear to circular models, emphasizing resource utilization and waste minimization. This trend is driven by stringent regulations like the EU's Circular Economy Action Plan and corporate sustainability targets, leading to greater investment in closed-loop systems and certified recycled resins.

- Rapid expansion of advanced (chemical) recycling technologies: Innovations in chemical recycling, such as pyrolysis, depolymerization, and solvolysis, are enabling the processing of complex and contaminated plastic waste that mechanical methods cannot handle efficiently. These technologies break plastics down into their original monomers, allowing for the creation of near-virgin quality materials suitable for high-performance and food-grade applications.

-

Increasing demand from automotive and electronics industries: The automotive sector is a dominant application for recycled engineering plastics, with manufacturers using them for lightweight, durable components to reduce carbon emissions and meet environmental regulations. The electronics industry is also seeing significant growth, driven by e-waste recycling initiatives and the use of recycled polycarbonate and ABS in components like casings and connectors.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5929

Recycled Engineered Plastic Resins: Applications and Benefits

Recycled engineering plastics are like commodity plastic but have a better mechanical and thermal properties. These resins have become an essential component in the effort to create more sustainable and eco-friendly materials and are derived from post-consumer or post-industrial plastic waste, processed, and engineered to meet specific performance standards. Their use spans a variety of industries, each benefiting from the durability, versatility, and environmental advantages of these recycled materials.

1. Automotive Industry

In the automotive sector, recycled engineered plastic resins are used to manufacture various components, such as bumpers, dashboards, and interior trim. These materials provide the necessary strength and resilience while reducing the overall weight of vehicles, which can enhance fuel efficiency. Additionally, using recycled resins helps automotive manufacturers meet stringent environmental regulations and sustainability goals.

2. Consumer Electronics

The consumer electronics industry utilizes recycled plastic resins in the production of casings, connectors, and internal components of devices such as smartphones, laptops, and household appliances. These resins offer high impact resistance and thermal stability, ensuring that electronic products are durable and long-lasting. By incorporating recycled materials, electronics manufacturers can reduce their environmental footprint and promote recycling initiatives.

3. Construction

In construction, recycled engineered plastic resins are employed in the production of building materials such as pipes, insulation, and roofing membranes. These materials offer excellent durability, weather resistance, and insulation properties, making them suitable for a wide range of construction applications. Using recycled plastics in construction not only reduces the environmental impact but also contributes to creating energy-efficient and sustainable buildings.

4. Textiles

The textile industry uses recycled plastic resins to create fibers for fabrics used in clothing, upholstery, and carpeting. These fibers can be woven into various textures and patterns, providing both aesthetic appeal and functional performance. Recycled plastic fibers help reduce the dependence on traditional textile materials, such as cotton and wool, and support the development of a circular economy in the fashion industry.

6. Furniture

Recycled engineered plastic resins are also used in the manufacturing of furniture, including chairs, tables, and storage units. These materials offer strength, flexibility, and ease of maintenance, making them ideal for both indoor and outdoor use. By incorporating recycled plastics into furniture production, manufacturers can create products that are not only stylish and functional but also environmentally responsible.

Recycled Engineering Plastics Market Segmentation Insights

Market Segmentation

Product Type Insights

The polycarbonate (PC) segment led the market in 2024, due to its excellent strength, thermal stability, and impact resistance, making it suitable for high-performance applications. Recycled PC was widely used in automotive components, electrical and electronics housings, and construction materials, combining durability with sustainability. Advances in recycling processes improved the quality and consistency of recycled PC, allowing it to closely match virgin material properties.

The acrylonitrile butadiene styrene (ABS) segment is growing fastest over the forecast period, driven by its excellent impact resistance, dimensional stability, and versatility for various applications. Recycled ABS was widely adopted in automotive parts, consumer electronics, and household appliances, offering performance comparable to virgin materials.

Recycling Process Type Insights

In 2024, the mechanical recycling segment dominated the market, due to its cost-effectiveness and ability to produce high-quality materials on a large scale. This process involves shredding, washing, and reprocessing plastic waste into usable pellets, making it suitable for automotive, electronics, and construction applications. Advancements in sorting, cleaning, and processing technologies improved the consistency and performance of mechanically recycled plastics.

The chemical recycling segment is the second-largest segment, leading the market, due to its ability to convert plastic waste back into high-purity monomers, producing materials with properties comparable to virgin plastics. This method allows the recycling of complex and contaminated plastics that are difficult to process mechanically, expanding the range of usable waste. Advancements in catalysts, depolymerization technologies, and process efficiency enhanced the economic viability and quality of chemically recycled plastics.

Application Insights

The automotive segment led the market in 2024, due to the growing demand for lightweight and sustainable materials to improve fuel efficiency and reduce emissions. Recycled plastics were widely used in interior components, bumpers, dashboards, and under-the-hood applications, combining durability with cost-effectiveness. Increasing adoption of circular economy practices by automakers further boosted the use of high-performance recycled polymers.

The electrical & electronics segment is growing fastest over the forecast period, driven by the growing demand for lightweight, durable, and heat-resistant materials in consumer electronics and industrial devices. Recycled plastics were increasingly used in casings, connectors, circuit boards, and insulation components, offering performance comparable to virgin polymers. Rapid technological advancements and the rising production of electronic devices have fueled the adoption of sustainable plastic alternatives.

Regional Insights

Asia-Pacific’s Ascendancy: The Epicenter of the Recycled Engineering Plastics Boom

Asia Pacific dominated the market in 2024, driven by rapid industrialization and large-scale manufacturing across countries like China, India, and Japan. The region's strong automotive, electronics, and construction sectors fueled demand for sustainable and high-performance recycled plastics. Government initiatives promoting circular economy practices and plastic waste management further accelerated market growth. Additionally, the availability of low-cost labor and raw materials enhanced production efficiency and competitiveness.

China Recycled Engineering Plastics Market Trends

China's market in 2024 showed strong growth due to the country's expanding automotive, electronics, and construction industries. Rising environmental regulations and government initiatives promoting circular economy practices encouraged the adoption of recycled plastics. Technological advancements in sorting, chemical recycling, and material processing improved the quality and performance of recycled engineering plastics.

North America’s Recycling Renaissance: Fueling the Future of Engineering Plastics

North America emerged as the fastest-growing region in the market in 2024, driven by rising environmental awareness and strict government regulations on plastic waste. The automotive, electronics, and packaging industries are increasingly adopting recycled plastics to meet sustainability and circular economy goals. Technological advancements in chemical and mechanical recycling improved the quality and performance of recycled engineering plastics, expanding their industrial applications.

U.S. Recycled Engineering Plastics Market Trends

The U.S. market in 2024 experienced significant growth driven by increasing demand from the automotive, electronics, and construction sectors. Stricter environmental regulations and corporate sustainability initiatives encourage the use of recycled plastics to reduce waste and carbon footprint. Advances in chemical and mechanical recycling technologies improved the quality, durability, and performance of recycled engineering plastics.

Europe Recycled Engineering Plastics Market Trends

Europe is at the forefront of the recycled engineering plastics market due to its stringent environmental regulations and circular economy policies. The European Union’s Green Deal and Circular Plastics Alliance are driving industries to incorporate a higher percentage of recycled plastics in manufacturing processes. Directives such as the Waste Framework Directive and the Single-Use Plastics Directive are putting pressure on manufacturers to enhance recyclability and reduce plastic waste. Leading companies in automotive, electronics, and packaging are investing in closed-loop recycling models, while innovations in chemical recycling are allowing high-performance engineering plastics to be reused in critical applications without quality degradation.

➤ Contact Us: sales@towardschemandmaterials.com | ☎ +1 804 441 9344

Top Companies in the Recycled Engineering Plastics Market & Their Offerings:

- Eastman Chemical Company: Eastman utilizes advanced molecular recycling technologies to convert hard-to-recycle plastic waste into virgin-quality materials for various high-performance applications.

- Trinseo: Trinseo offers a portfolio of sustainably-advantaged engineering plastics, including PC and PC/ABS grades, that incorporate post-consumer and post-industrial recycled content.

- Veolia Environnement: Veolia provides end-to-end plastic recycling solutions, producing ready-to-use circular polymers under its PlastiLoop brand for industries like automotive and electronics.

- Borealis: Borealis leverages its proprietary Borcycle™ mechanical and chemical recycling technologies to transform post-consumer waste into high-quality, virgin-like polyolefin materials.

- Dow Inc.: Dow incorporates mechanically and chemically recycled feedstocks into its product lines to produce high-performance, sustainable polymers that meet stringent quality specifications.

- Indorama Ventures: Indorama Ventures is a major player in PET recycling, converting billions of plastic bottles annually into high-quality rPET flakes and pellets for packaging and fibers.

-

Alpek S.A.B. de C.V.: Alpek integrates recycling capacity into its business model to produce food-grade recycled content (rPET) for its PET packaging and polyester operations.

More Insights in Towards Chemical and Materials:

- Recycled PET Flakes Market Size to Surge USD 36.06 Billion by 2034

- Recycled Plastics Market Size to Reach USD 183.80 Billion by 2034

- Recycled PET (rPET) Market Size to Surge USD 29.19 Billion by 2034

- Recycled Polystyrene Market Size to Hit USD 7.49 Bn by 2034

- Recycled Plastics In Green Building Materials Market Size and Share 2034

- Recycled thermoplastics Market Size to Exceed USD 145.34 Bn by 2034

- Recycled Polyester Market Size to Hit USD 38.53 Bn by 2034

- Recycled Polyolefin Market Size to Reach USD 144.2 Billion by 2034

- Commodity Plastics Market Size to Hit USD 666.76 Billion by 2034

- Mechanical Recycling of Plastics Market Size to Surge USD 92.86 Bn by 2034

- Biodegradable Plastics Market Size to Reach USD 91.26 Billion by 2034

- Plastics Market Size to Worth USD 984.11 Billion by 2034

- U.S. Plastics Market Size to Surge USD 131.34 Billion by 2034

- U.S. Recycled Plastics Market Size to Reach USD 131.33 Bn by 2034

- Recycled Plastics Market Size to Reach USD 183.80 Billion by 2034

- Sustainable Plastics Market Size to Hit USD 1,448.23 Bn by 2034

- Circular Plastics Market Size to Hit USD 182.21 Billion by 2034

- Transparent Plastics Market Size to Hit USD 245.19 Bn by 2034

- Recycled Plastics In Green Building Materials Market Size and Share 2034

- Europe Bioplastics Market Volume to Reach 40.16 Million Tons by 2034

- Plastics Extruded Market Size to Surge USD 259.21 Billion by 2034

- Asia Pacific Bioplastics Market Volume to Reach 11.13 Million Tons by 2034

- Europe Plastic Market Size to Surpass USD 223.02 Bn by 2034

- Recycled thermoplastics Market Size to Exceed USD 145.34 Bn by 2034

- U.S. Recycled Plastics Market Size to Reach USD 131.33 Bn by 2034

- Europe Recycled Plastics Market Size to Surpass USD 33.84 Bn by 2035

- U.S. Recycled Polyester Market Size to Surpass USD 7.16 Bn by 2034

- Asia Pacific Recycled Plastics Market Size to Surpass USD 72.11 Bn by 2034

- Recycled Engineering Plastics Market Size to Hit USD 7.89 Billion by 2034

- Recycled Plastic Pipes Market Size to Hit USD 20.08 Billion by 2034

- U.S. Recycled Polyethylene Terephthalate Market Size and Share 2034

- U.S. Recycled Plastics in Green Building Materials Market Size and Share 2034

Recycled Engineering Plastics Market Top Key Companies:

- MBA Polymers, Inc.

- Banyan Nation

- Polyplastics Group

- Covestro AG

- Eastman Chemical Company

- Trinseo

- Veolia Environnement S.A.

- Borealis

- Dow Inc.

- Polyvisions Inc.

Recent Developments

- In February 2025, Polyplastics Co., Ltd. announced the launch of a new 40% glass-filled recycled PPS (polyphenylene sulfide) compound. The material aimed to meet rising demand for sustainable materials in automotive and other applications. Polyplastics emphasized strict quality control during production. They also hinted at plans to release higher glass-filled grades in the future.

- In August 2023, Polyplastics, a Japanese engineering plastics manufacturer, announced the launch of its "Duracircle" recycling service, which was scheduled to commence in March 2024. This service enables Polyplastics' customers to recycle industrial waste materials from their production processes by re-compounding them.

- In October 2025, BASF and its cooperation partners presented their two pioneering technologies for enabling the recycling of polyamides from end-of-life vehicles at this year’s K 2025. These technologies are designed to change, especially in view of the upcoming regulatory requirements of the End-of-Life Vehicle Regulation (ELVR).

Recycled Engineering Plastics Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2034. For this study, Towards Chemical and Materials has segmented the global Recycled Engineering Plastics Market

-

Product Outlook (Volume, Kilotons; Revenue, USD Million, 2020 - 2034)

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyamide (Nylon)

- Polyethylene Terephthalate (PET)

- Polybutylene Terephthalate (PBT)

- Others

-

Recycling Process Outlook (Volume, Kilotons; Revenue, USD Million, 2020 - 2034)

- Mechanical Recycling

- Chemical Recycling

-

Application Outlook (Volume, Kilotons; Revenue, USD Million, 2020 - 2034)

- Automotive

- Electrical & Electronics

- Building & Construction

- Consumer Goods

- Industrial Machinery

- Others

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5929

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.